Environmental Targets for 2030

Environmental Targets for 2030

- Sustainability

- Our priorities

- Global environment

- Environmental Targets for 2030

| Theme | Target | |||||||

|---|---|---|---|---|---|---|---|---|

| FY2021 actual | FY2022 actual | FY2023 actual | FY2024 actual | Revised target for FY2030 | ||||

| Preventing global warming | Reduce greenhouse gas emissions in the supply chain | |||||||

|

-7.3% compared with FY2016 |

-8.6% compared with FY2016 |

-18.6% compared with FY2016 |

-20.7% compared with FY2016 |

-50% compared with FY2016 |

|||

|

|

|

|

|

-25% (starting with Categories 1 and 4) compared with FY2020 |

|||

|

||||||||

| Promote the use of renewable energy | ||||||||

|

|

|

|

|

100% | |||

|

|

|

|

|

– | |||

| Establishing resource recycling | Promote recycling in production processes | |||||||

|

99.8% | 99.8% | 99.9% | 99.6% | At least 99% | |||

|

|

|

|

|

– | |||

| Efficiently use water resources for production | ||||||||

|

-13.1% compared with FY2016 |

-15.4% compared with FY2016 |

-10.8% compared with FY2016 |

-9.5% compared with FY2016 |

-16% compared with FY2016 |

|||

| Plant resources/nature conservation | Promote sustainable raw material procurement | |||||||

| • Promote sustainable palm oil procurement | ||||||||

|

54.9% (Jan–Dec 2021) | 59.6% (Jan–Dec 2022) | 66.9% (Jan–Dec 2023) | 77.7%(Jan–Dec 2024) |

100% | |||

|

49.6% (Jan–Dec 2021) | 51.1% (Jan–Dec 2022) | 56.3% (Jan–Dec 2023) | 70.5% (Jan–Dec 2024) |

50% | |||

|

Palm oil: 68.5% Palm kernel oil: 30.5% |

Palm oil: 90.9% | Palm oil: 92.7% | Palm oil: 92.9% | Palm oil: 100% | |||

|

|

|

|

|

Sustainable soybean procurement predicated on stable supply | |||

|

|

|

|

|

Sustainable cacao procurement predicated on stable supply | |||

| Promote natural conservation activities | ||||||||

|

|

|

|

|

– | |||

| Promoting environmentally conscious development | Reduce plastic containers/packaging and promote resource recycling | |||||||

|

|

|

|

|

|

|||

|

|

|

||||||

|

|

|

||||||

| Develop products/services that use plant resources and have a positive environmental impact | ||||||||

|

|

|

|

|

Products/services that have a positive environmental impact become the core driving force of growth | |||

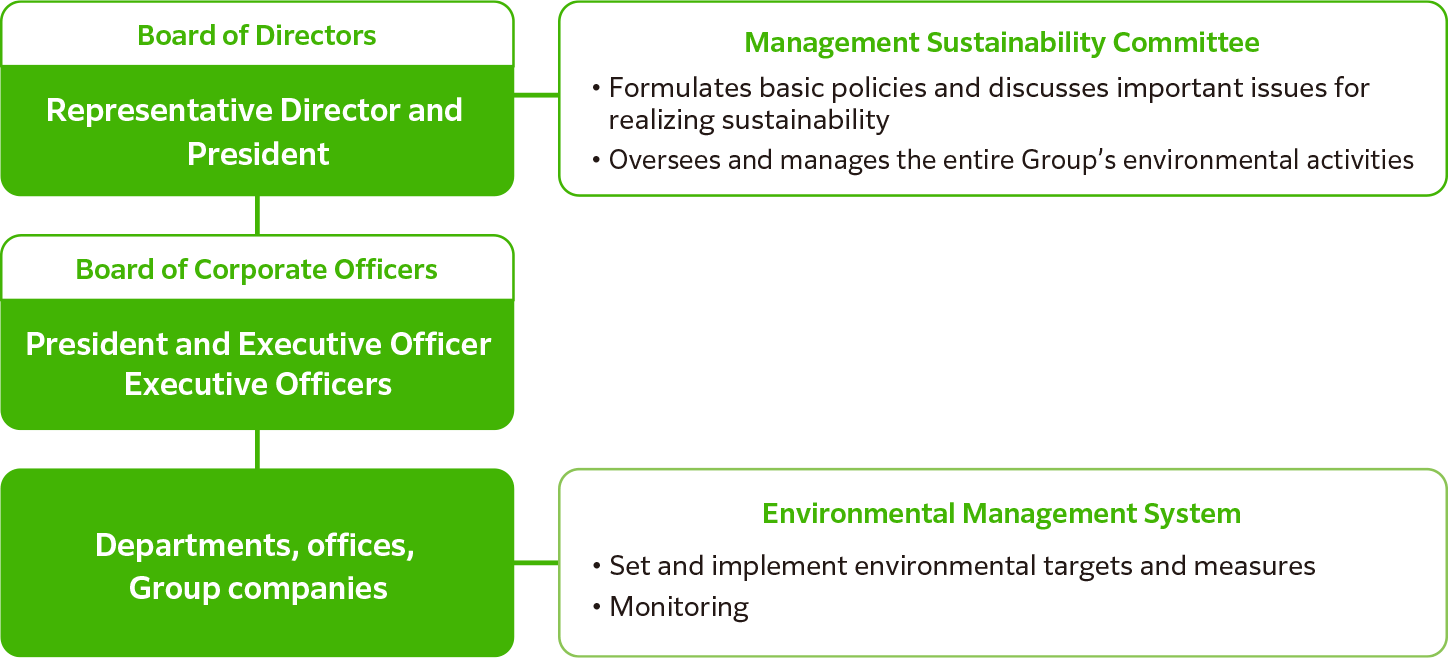

Environmental management promotion system

The Group’s Business Strategy Council sets out environmental policies to achieve the sustainable growth of the Group and sustainable development of society (sustainability). The council also oversees and manages the environmental activities of the entire Group. In response to these environmental policies, each department, office, and Group company has established an environmental management system under which they set out, implement, and monitor environmental targets and measures.

Acquiring environmental management certifications

The Nisshin OilliO Group has acquired ISO 14001 and other environmental management system certifications and implements activities based on an environmental management program. Since 2000, we have made efforts to acquire certification for each of our production plants, and in FY2009, we integrated our production plants and distribution centers (i.e. made them multi-sites) to create a system for centrally managing environmental targets and regulations and other key monitoring items. We will continue to promote certification to Group companies.

| System | Certification date | Organizations |

|---|---|---|

| ISO 14001 | September 2009 (Multi-site integration certification) |

The Nisshin OilliO Group, Ltd. Yokohama Isogo Complex Nagoya Plant Sakai Plant Mizushima Complex Distribution centers (Tohoku-Ishinomaki, Fukuoka) |

| February 2013 | IQL | |

| September 2018 | ISF (Port Klang Plant) | |

| October 2018 | ISF (Dengkil Plant) | |

| Eco-Action 21 | January 2014 | Nakai Plant, Daito Cacao Co., Ltd. |

ISF: Intercontinental Specialty Fats Sdn. Bhd.

IQL: Industrial Química Lasem, S.A.U.